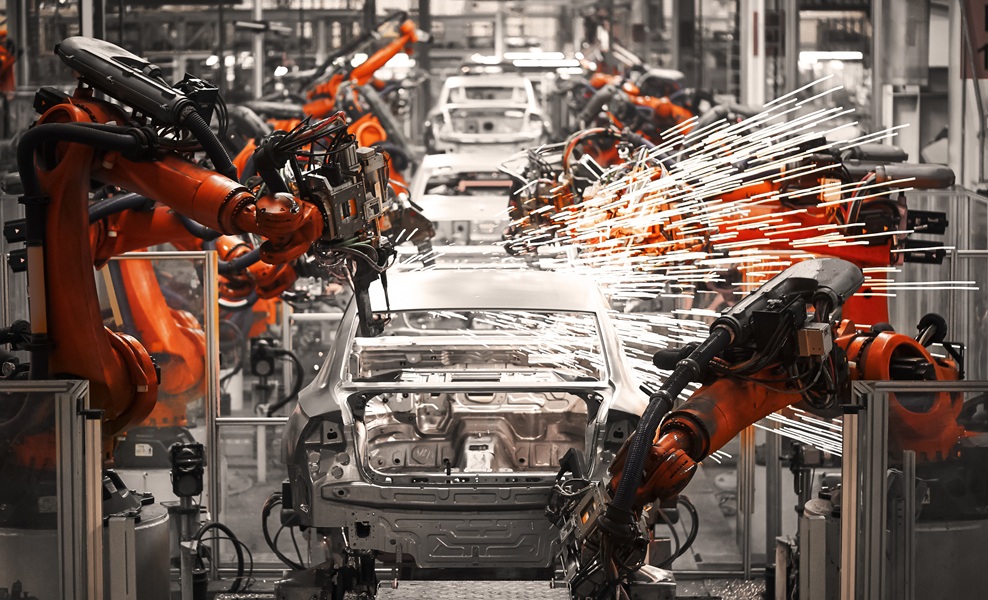

As digital transformation accelerates, advanced simulation, data management, and automated inspection are reshaping automotive production, cutting costs, reducing waste, and improving time-to-market for new models. As Mark Venables explains this shift highlights the power of digital tools to enhance both operational efficiency and environmental responsibility in the industry.

As automotive manufacturers adapt to a rapidly evolving digital landscape, partnerships between technology innovators and carmakers are helping them keep pace with the demands of Industry 4.0. For SEAT, its ongoing collaboration with Hexagon has spanned more than 25 years, transforming how the automotive giant approaches quality control, efficiency, and the integration of digital tools in manufacturing. Recently, Hexagon and SEAT signed a strategic agreement focused on the advanced digitalisation of vehicle components, enhanced data management, and process simulation – marking a significant step forward in SEAT’s manufacturing evolution. Ignazio Dentici, Vice President, Global eMobility and Automotive at Hexagon’s Manufacturing Intelligence division, shared insights on this transformative partnership and how it’s setting new standards in automotive production.

Embracing a new era of predictive manufacturing

The cornerstone of the partnership lies in Hexagon’s digital twin technology, a tool that blends real-world data with simulations to create a virtual model of the vehicle assembly process. This powerful innovation enables SEAT’s engineers to refine production methods and optimise manufacturing processes long before vehicles hit the assembly line. Dentici explains the advantages: “Now, through our extended collaboration, we will work together to integrate a digital twin that applies metrology data with process simulations to predict outcomes and improve manufacturing efficiency. SEAT’s process engineers are able to plan production processes, digitise the car body and its components, and surface that data through reports and analytics that help production personnel drive efficiency and reduce costs from pilot into volume production.”

This approach ensures that production decisions can be based on precise, real-time insights, minimising costly delays and waste. Dentici points out that this capability goes beyond traditional quality assurance measures, bringing a level of predictive accuracy that can streamline production timelines and improve product quality. “Hexagon’s process simulation solutions are used by SEAT to optimise production with a virtual prototype of the product, speeding up the process of adjusting the production methods. This means a significant reduction in prototyping costs, a reduction in material waste, and an improvement in the time-to-market for the new vehicle models.”

Integrating automation with Hexagon’s PRESTO system

At the heart of SEAT’s enhanced quality control is Hexagon’s PRESTO system, a state-of-the-art robotic inspection solution that automates 3D laser scanning for the car body. Traditional inspection methods can be labor-intensive and prone to errors, making the need for a more scalable, automated approach critical. According to Dentici, the PRESTO system brings much-needed accessibility and flexibility to robotic inspection: “One of the really exciting things about PRESTO is how it makes robotic automation inspection more accessible – both to the expert metrologist that needs to set them up and to the technician on the shop floor who can load the system. The automated robotic programming enables just a single metrology specialist to create and deploy a reliable and safe program to a fully automated quality inspection cell in a matter of hours.”

The flexibility of the PRESTO system extends to its scalability, making it suitable for automotive OEMs and suppliers of varying sizes. With modular components and an intuitive interface, this turnkey solution allows SEAT to integrate additional inspection modules as production demands increase. Dentici highlights the system’s adaptability as a critical benefit for manufacturers, particularly in an industry facing a skills shortage: “The integrated robotic system eliminates repetitive manual setup and calibration processes, enabling teams to work more effectively and focus on operational excellence while also halving total inspection time compared to other modern inspection technologies.”

PRESTO’s compatibility with existing metrology and quality assurance software allows SEAT to easily incorporate it into its current systems. This integration means smaller manufacturers can adopt automated, large-volume inspection without needing extensive robotics expertise, a significant advantage as the automotive sector continues to evolve towards complete inline inspection. “Production can’t wait for quality inspection bottlenecks if you’re making a car in less than two minutes,” Dentici adds. “PRESTO has integrated several key technologies to make very fast nearline inspection possible, and such systems are gradually moving inline – but this is not to be taken lightly; it’s a big step and business-critical.”

Centralising data for intelligent decision-making

Data management forms another pillar of Hexagon and SEAT’s partnership. With Hexagon’s eMMA platform, SEAT’s production teams can capture, manage, and analyse data from a wide range of measurement systems, including those from third-party providers. This consolidated approach to data collection allows SEAT to monitor parts at each stage of the assembly process, identify potential quality issues, and make informed adjustments in real time. Dentici explains: “SEAT leverages Hexagon’s eMMA data management software to automatically capture metrology data from its systems and manage it in a standardised way, with traceability of constituent parts such as doors and their integration into each car they produce. This process supports informed and efficient decision-making and enables quality teams to monitor trends and optimise quality in all phases of assembly.”

By ensuring that all relevant data is readily accessible, SEAT’s production and quality teams can respond swiftly to changing conditions or unexpected issues on the production line. Dentici describes this approach as a crucial shift towards data-driven quality assurance: “Now we will not only acquire data about the quality of our parts faster and more accurately, but we will also be able to improve manufacturing performance with them. This predictive approach to quality allows us to improve our customer satisfaction as well as significantly reduce the materials used in the manufacturing process, reinforcing our commitment to sustainability.”

Leveraging digital twins for smarter, sustainable manufacturing

For SEAT, Hexagon’s digital twin technology represents a significant leap towards more efficient and sustainable production. Using virtual prototypes, SEAT can fine-tune assembly processes and minimise reliance on physical prototyping, reducing waste and accelerating time-to-market. This shift allows SEAT to refine manufacturing methods in a controlled, digital environment, avoiding potential delays and costly reworks on the shop floor.

“The automotive industry’s goal is to inspect and fully digitise every car and its components,” Dentici notes. “PRESTO has integrated several key technologies to make very fast nearline inspection possible. Such systems are gradually moving inline, and this transition requires precision and reliability at every stage. Digital twins enable manufacturers to predict outcomes and identify issues before they arise, saving time, reducing waste, and ensuring high-quality products roll off the line.”

As digital twins become central to SEAT’s manufacturing strategy, their impact is evident not only in production efficiency but also in supporting SEAT’s sustainability targets. Hexagon’s digital solutions enable SEAT to take a predictive approach to quality control, minimising material waste and lowering carbon footprints across its operations. “This is about creating a resilient, future-ready manufacturing process that prioritises quality, sustainability, and efficiency,” Dentici explains. “Our partnership with SEAT is helping to redefine automotive manufacturing by aligning operational excellence with environmental responsibility.”

Transforming the automotive landscape

Hexagon’s collaboration with SEAT is a prime example of how advanced digital tools can drive tangible improvements across the automotive value chain. From quality assurance to data management, digital twins, and robotic inspection, SEAT’s Martorell plant is setting new standards in how manufacturing can adapt to the challenges of a digital-first world. As Dentici summarises, “We are at a pivotal time in the automotive industry’s transformation towards smarter, more connected, and efficient production. Our work with SEAT represents not just a technological partnership but a shared commitment to sustainability and operational excellence that will define the future of automotive manufacturing.”

The partnership between Hexagon and SEAT highlights the growing importance of digital innovation in automotive manufacturing, laying the groundwork for a more sustainable and resilient industry. By leveraging predictive manufacturing, data-driven decision-making, and automated inspection, SEAT is enhancing its capacity to produce high-quality vehicles while staying true to its environmental commitments. In a rapidly evolving sector, the integration of Hexagon’s advanced technologies positions SEAT to lead the way in next-generation automotive production, setting a benchmark for manufacturers worldwide.