Autonomous mobile robots will power the warehouse automation market over the next five years and generate $41 billion by 2027.

Autonomous mobile robots, AGV, ASRS and picking systems are set to have the highest share of the market in 2025 and grow at 15 per cent over the next five years, according to latest LogisticsIQ 2022 Warehouse Automation Market report

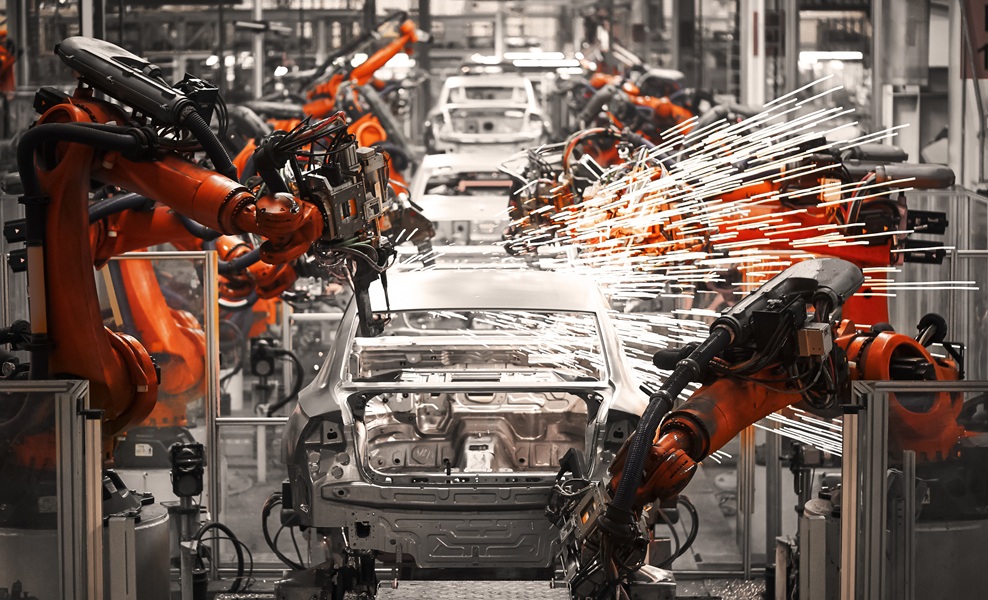

Autonomous mobile robots are increasingly used to improve process speed and efficiency in warehousing, agriculture, healthcare, production, bottling plants, printing, retail, marine and airports and are vital to material handling and manufacturing operations across a wide range of industries.

“Automation is no longer just for big business, any manufacturing or logistics company can seamlessly create a hybrid workforce that truly is fit for the future,” says Dr. Paul Rivers, managing director of Guidance Automation whose solutions enable the automation of robotic vehicles, forklift trucks, floor cleaning equipment and all types of mobile moving systems used in industry.

Autonomous Mobile Robots (AMRs) align with Industry 4.0 aims, providing scalable transport platforms that can be dynamically optimized according to changing operational demands.

“AMRs help you work smarter; they help focus resources on value-add tasks, reduce errors, increase throughput and, ultimately, maximize operational efficiency,” says Peter Moore, commercial manager at Guidance Automation. “Ultimately they provide the opportunity for integrated, collaborative material handling solutions that optimise and streamline resource usage and processes”.

Guidance Automation has become the first reseller of OTTO Motors’ Autonomous Mobile Robots in the UK. OTTO Motors provides AMR’s for material handling inside manufacturing facilities and warehouses.

The AMRs will be offered with Guidance Automation’s attachments and support services for a complete solution for material handling automation. Guidance Automation’s attachments include briNgbot and iNcaart, which enable businesses to enhance their AMRs with new functionality including light-directed picking modules and shelves to transport multiple totes or shipping cartons. Additionally, iNcaart provides a conveyor-top for AMRs for efficient and adaptable payload transfer from conveyor-to-conveyor or vehicle-to-vehicle loads.