The Red Sea crisis has once again exposed the fragility of global supply chains, forcing companies to rethink logistics strategies. Mark Venables discovers how graph databases are emerging as a crucial tool, offering real-time insights, predictive capabilities, and the agility needed to navigate growing geopolitical uncertainty.

The disruption of maritime traffic in the Red Sea has once again exposed the fragility of global supply chains. The rerouting of shipments around Africa’s Cape of Good Hope has driven up costs, extended delivery times, and placed additional strain on industries dependent on just-in-time deliveries. The challenges posed by this crisis are not new, yet businesses still struggle to build the resilience required to withstand such shocks. Predictive technologies, particularly graph databases, are emerging as a critical tool in mitigating supply chain risks and enhancing operational agility.

Building resilience through visibility

The vulnerabilities of modern supply chains have been repeatedly exposed in recent years, from the COVID-19 pandemic to geopolitical disruptions such as Brexit and the war in Ukraine. Joe Depeau, Senior Engineer at Neo4j, sees these events as a stark reminder of the need for a more proactive approach to supply chain management. “Global supply chains have become increasingly vulnerable to geopolitical tensions and world events, as demonstrated by various disruptions in the last few years like empty supermarket shelves during COVID-19 and the Red Sea blockades,” he says. “These incidents underscore the critical need for comprehensive supply chain resilience and protection.”

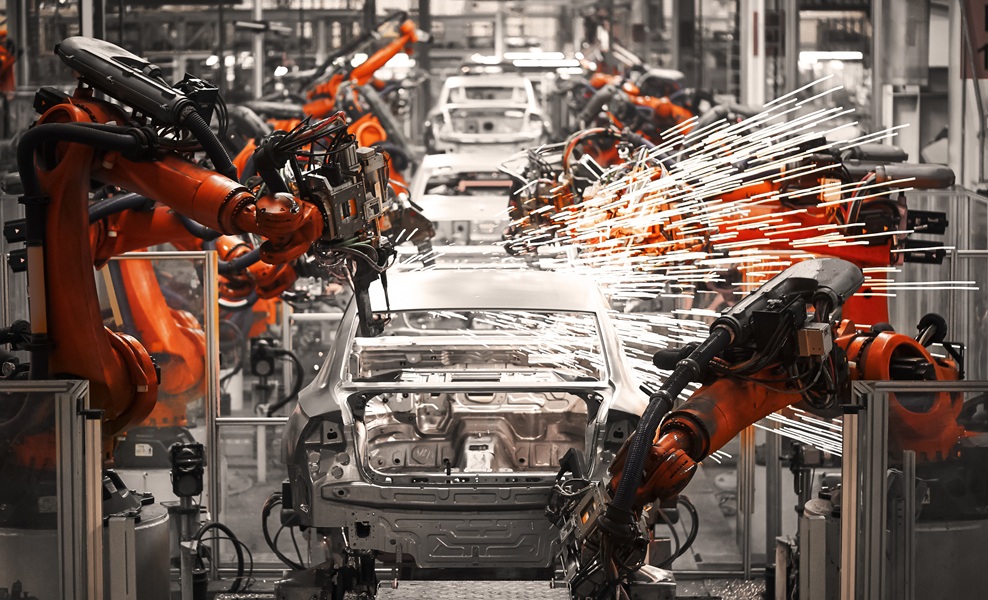

Depeau explains that companies that prioritise end-to-end visibility can better predict and mitigate potential disruptions. “To safeguard against potential risks, businesses must adopt a multi-faceted approach focusing on regulatory compliance, end-to-end visibility, and technological innovation,” he says. “Following stringent regulations, such as EU legislation, ensures thorough vetting and monitoring at every stage of the supply chain. For instance, in automotive manufacturing, this means tracking materials from their origin in Africa through to final production in Germany.”

The ability to visualise a supply chain in its entirety is key to identifying weak points before they become critical failures. Advanced digital tools, particularly graph databases, provide the level of insight required to minimise the impact of unexpected challenges and create more adaptable supply networks.

The power of graph databases

Traditional supply chain management relies on structured data models, often struggling to capture the complexity of interconnected global networks. Graph databases present a different approach, mapping supply chains as dynamic ecosystems rather than rigid, linear systems. “Traditional data models usually operate on a system of tables with columns and rows – struggling with complex supply chain networks and often failing to capture intricate relationships,” Depeau says. “Graph databases like Neo4j solve this problem by visualising data as connected networks.”

Unlike relational databases, which can become cumbersome when processing large, interdependent datasets, graph databases allow businesses to analyse multiple connections simultaneously. “By analysing multiple connections simultaneously, graph databases uncover insights hidden in conventional data models,” Depeau continues. “This means businesses can track materials, predict risks, and make smarter decisions faster.”

Neo4j, for example, enables companies to compute efficient paths through supply networks, rapidly identifying bottlenecks and alternative routing options. It transforms supply chain data from static records into dynamic, actionable intelligence. Its ability to compute efficient paths directly translates into time and cost savings, helping organisations build more resilient and adaptable supply chains.

Predicting and preventing disruption

With geopolitical instability showing no signs of abating, the ability to anticipate and respond to supply chain shocks is critical. Graph databases, particularly when combined with digital twin technology and real-time data inputs, are becoming essential tools for predictive analytics in supply chain management. “Graph databases offer powerful insights for supply chain management by efficiently analysing routes and spotting pinch points,” Depeau explains. “They enable real-time analysis of complex scenarios, such as potential disruptions from geopolitical events like Brexit or the Ukraine war.”

By creating a digital twin of their supply chain, businesses can simulate different scenarios and develop contingency plans. By using graph technology to create digital twins of their existing supply chains, businesses can simulate different scenarios and predict potential challenges. “This allows them to track shipping routes in real-time, allowing companies to quickly recalculate paths if a route takes longer than expected,” Depeau says. “They can send these instructions to IoT sensors on deck, allowing them to change their route in real-time. This approach transforms supply chain management from a reactive to a proactive strategy.”

This level of agility is crucial for companies operating in unpredictable environments. By continuously analysing real-time data, businesses can detect early warning signs and adjust their logistics accordingly. According to Depeau the key advantage here is agility: businesses gain the ability to see potential problems before they occur and develop strategic responses quickly and efficiently.

Future-proofing supply chains with AI

As supply chains grow more complex, the integration of AI-driven models with graph databases will further enhance predictive capabilities. AI’s ability to process vast amounts of historical and real-time data enables businesses to model different scenarios and optimise decision-making.

“GraphRAG technology, which optimises the output from LLMs, will play a key role in the future success of all Generative AI technologies,” says Depeau. “By grounding large language models with knowledge graphs, companies can generate accurate, predictive responses to complex scenarios. The application of AI and graph databases extends beyond risk mitigation. These technologies enable companies to optimise logistics, identify inefficiencies, and reduce operational costs. AI’s ability to analyse past behaviours and model future practices enables businesses to anticipate and respond to unexpected challenges like geopolitical crises or port closures. These technologies can replicate multiple potential outcomes and recommend optimal strategies, transforming decision-making processes.”

Integrating AI with supply chain technology will further enhance real-time decision-making. By combining predictive analytics, historical data, and real-time monitoring, companies can refine their supply chain strategies in ways previously unattainable. Graph databases will continue to play a pivotal role in this transformation, enabling businesses to build detailed supply chain models that factor in multiple variables simultaneously.

Adoption is no longer optional. Companies that fail to integrate these technologies risk being left behind. The recent Red Sea disruptions forced major retailers like Ikea and Next to warn of potential impacts, while Tesla suspended manufacturing at its European car factory. “Companies that fail to consider graph technology risk significant supply chain vulnerabilities, as recent events demonstrate,” says Depeau. “These incidents underscore the critical importance of using a graph database to develop alternative solutions. Businesses that act quickly can maintain their competitive edge, while those who remain reactive face increased costs, missed opportunities, and potential customer service failures.”

As geopolitical uncertainty continues to shape global trade, businesses must take a more strategic approach to supply chain management. Graph databases, digital twins, and AI-driven predictive models offer a way forward, transforming supply chains from vulnerable, reactive systems into agile, resilient networks capable of withstanding the next inevitable disruption.