Rockwell Automation is transforming manufacturing through AI-driven design tools, software-defined automation, and virtual commissioning technologies. Mark Venables explains how these innovations enhance efficiency, collaboration, and productivity while reducing complexities and integration challenges in automation development.

From AI-driven design tools to software-defined automation, the latest innovations are shaping the future of manufacturing and industrial operations. These advancements are transforming the industry by driving efficiency, enhancing collaboration, and addressing long-standing challenges in automation development.

“We have been doing a lot in the design space,” Matheus Bulho, Senior Vice President of Software & Control at Rockwell Automation, begins, explaining how Rockwell redefines automation development through innovative methods akin to DevOps. “Often in automation projects, different teams work on separate parts of the code, and integration happens only at the very end when the machine should already be up and running,” he explains. “This fragmented approach frequently leads to integration issues, inflating costs and delaying machine readiness. To address these challenges, Rockwell has implemented continuously integrated content that allows multiple contributors to work on the same codebase seamlessly.”

With tools like FactoryTalk Design Studio, Rockwell creates a collaborative environment reminiscent of cloud-based office platforms. “We can provide an Office 365-like experience for automation, integrating version control directly into the development tools,” Bulho says. “Engineers can continuously test, update, and ensure the code is always ready, eliminating many common pitfalls traditionally associated with machine commissioning. By adopting this approach, Rockwell significantly reduces the complexity and time it takes to bring a machine online.”

Virtual representations for smarter design

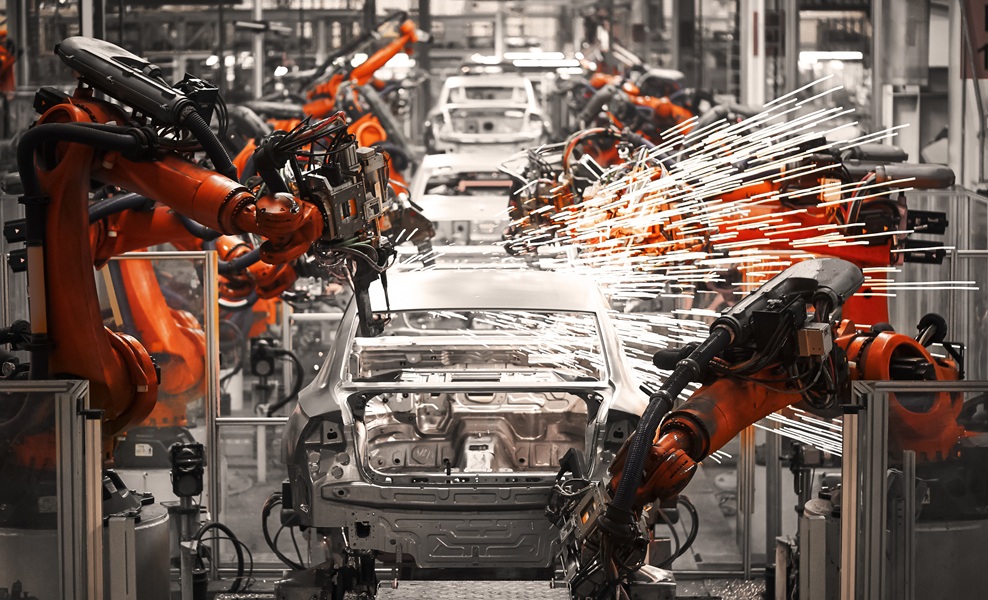

Another key area where Rockwell is driving transformation is the utilisation of virtual representations throughout the design process. “We have an entire stack that allows you to design and commission systems virtually,” Bulho adds, highlighting Rockwell’s Echo system and Emulate3D. “These tools offer high-fidelity virtual representations of devices like IO and drives, facilitating virtual commissioning of entire production lines.”

Rockwell’s partnership with Nvidia has taken virtual commissioning a step further. “By integrating Emulate3D with Nvidia Omniverse, we can bring multiple machine models into a single virtual production line,” he adds. “This enables detecting and correcting issues early, long before any physical prototypes are built. The cost and complexity of making changes during the physical commissioning stage are vastly reduced when adjustments can be made virtually.

“We are pushing the boundaries of what can be done with virtual commissioning. Using the Nvidia Omniverse, customers can visualise and test entire production lines in a virtual environment. This means every aspect of a machine’s performance can be validated before physical construction, reducing the risk of unexpected issues and ensuring a smoother commissioning process.”

AI as a co-pilot in automation design

Integrating artificial intelligence into the automation design process represents one of Rockwell’s most exciting developments. “We are bringing co-pilot capabilities to our design environment, particularly in FactoryTalk Design Studio,” Bulho explains. “This involves an agent-based approach where users can prompt the tool to create and explain content. For example, you can prompt FactoryTalk Design Studio to generate content, but just as importantly, it can explain the generated content.”

This feature addresses a key issue in modern industrial operations: the disconnect between system designers and those responsible for its maintenance and operation. “The person designing a system is often not the one operating it later on,” Bulho points out. By incorporating explainable AI, Rockwell ensures that the content generated is understood across teams, bridging the gap between design and operation.”

The company also envisions a future where AI plays an even more active role. “We plan to expand this to include additional autonomous agents capable of creating code based on a company’s specific requirements,” Bulho reveals. “These agents will generate content and create unit tests, ensuring that the code meets the necessary standards throughout the development pipeline. This promises a leap in productivity for automation system developers, as repetitive tasks are automated, and more robust, self-aware systems are created.”

The evolution of software-defined automation

Rockwell has long been at the forefront of software-defined automation, a concept that continues to evolve with new capabilities. “Software-defined automation is a broad concept for us,” Bulho says. Decades ago, Rockwell introduced the first tag-based control system, which allowed developers to create logic that was independent of specific hardware configurations. Today, this philosophy is furthered with FactoryTalk Design Studio.

“You can create logic abstracted not only from the IO but also from where the logic runs,” Bulho elaborates. “The application can be deployed across multiple controllers without altering the software, providing unparalleled flexibility. Rockwell’s hardware solutions, such as the Flex 5000 HA, also embody this software-defined approach.” You can define the function of each piece in software, whether it is an analogue input, output, or digital signal, Bulho explains, illustrating the seamless integration between software and hardware.

Similarly, Rockwell’s visualisation system, Optix, offers flexibility in deployment. “Users create a single visualisation runtime, and it does not matter whether it ends up on proprietary systems or open platforms,” Bulho explains. This adaptability is crucial for modern industrial environments, where solutions must be tailored to the specific needs of each facility.

From ArmorBlock hardware to autonomous control

On the hardware front, Rockwell is making strides with its ArmorBlock products, such as Armour Kinetix and Armor PowerFlex. “These products reduce or eliminate the need for cabinets, making equipment construction simpler,” Bulho notes. “Rockwell has introduced economical solutions to simplify wiring processes for applications that still require cabinets. We significantly reduce the setup time and installation costs by eliminating complex cabinets and creating products that can be mounted directly on machines.”

The Armor product line is part of Rockwell’s commitment to making industrial equipment easier to use and maintain. One example of how these technologies come together is the Delkor Top Loader System. “It provides a seamless integration of automation functions,” Bulho says.

In terms of autonomous control, Rockwell’s LogixAI is a breakthrough. “LogixAI allows for the optimisation of control functions without pre-determined programming,” Bulho says. “The system uses machine learning to understand the relationship between inputs and optimise outputs, enabling autonomous adjustments without human intervention. This complements our vision AI capabilities, allowing not only detection of issues but also autonomous corrections,” Bulho adds, illustrating the future of self-sustaining automation systems.”

Optimising performance with predictive maintenance

Predictive maintenance is another area where Rockwell is making significant progress. “Guardian AI is our latest offering focused on maintenance,” Bulho continues. By using existing sensors, both hard and soft, Guardian AI can detect potential maintenance needs before failures occur. The initial implementation of Guardian AI supports integration with our PowerFlex devices, and Rockwell plans to expand it to cover more devices over time.

This predictive approach helps customers avoid reactive maintenance, reducing downtime and maintenance costs. “When combined with our CMMS offering, Fiix, it automates maintenance workflows, including creating and managing work orders,” Bulho explains. “This integrated system ensures that issues are addressed promptly, streamlining the maintenance process from detection to execution.

“The goal is not just to detect when components need attention but to do so to prevent disruptions. Predictive maintenance with Guardian AI means you’re always a step ahead. This forward-thinking approach helps companies minimise downtime and maintain continuous production, essential for staying competitive in today’s market.”

Towards optimised production lines

Rockwell Automation’s ultimate vision is to optimise not just individual machines but entire production lines. “Our next step is the optimisation of entire lines and plants,” Bulho reveals. This involves integrating systems like LogixAI, Vision AI, and Guardian AI to provide real-time monitoring, predictive maintenance, and autonomous process optimisation.

“When data flows seamlessly from machines to analytics tools and back to control systems, you create a feedback loop that continuously adjusts operations. This holistic approach represents a shift from traditional automation, where each machine operated largely in isolation. Instead, Rockwell aims to create interconnected facilities where every component works together to achieve optimal performance.”

For manufacturers, the implications are profound. “Our goal is to provide the tools necessary for companies to create smart, interconnected facilities,” Bulho concludes. “By offering solutions that enhance collaboration, virtual commissioning, AI integration, and predictive maintenance, we are helping its customers navigate the complexities of modern automation and take full advantage of digital transformation.”

As the industry evolves, Rockwell’s focus on innovation, flexibility, and holistic optimisation positions it at the forefront of the automation revolution, delivering technologies that not only enhance operational efficiency but also lay the groundwork for the factories of the future.